About Behl

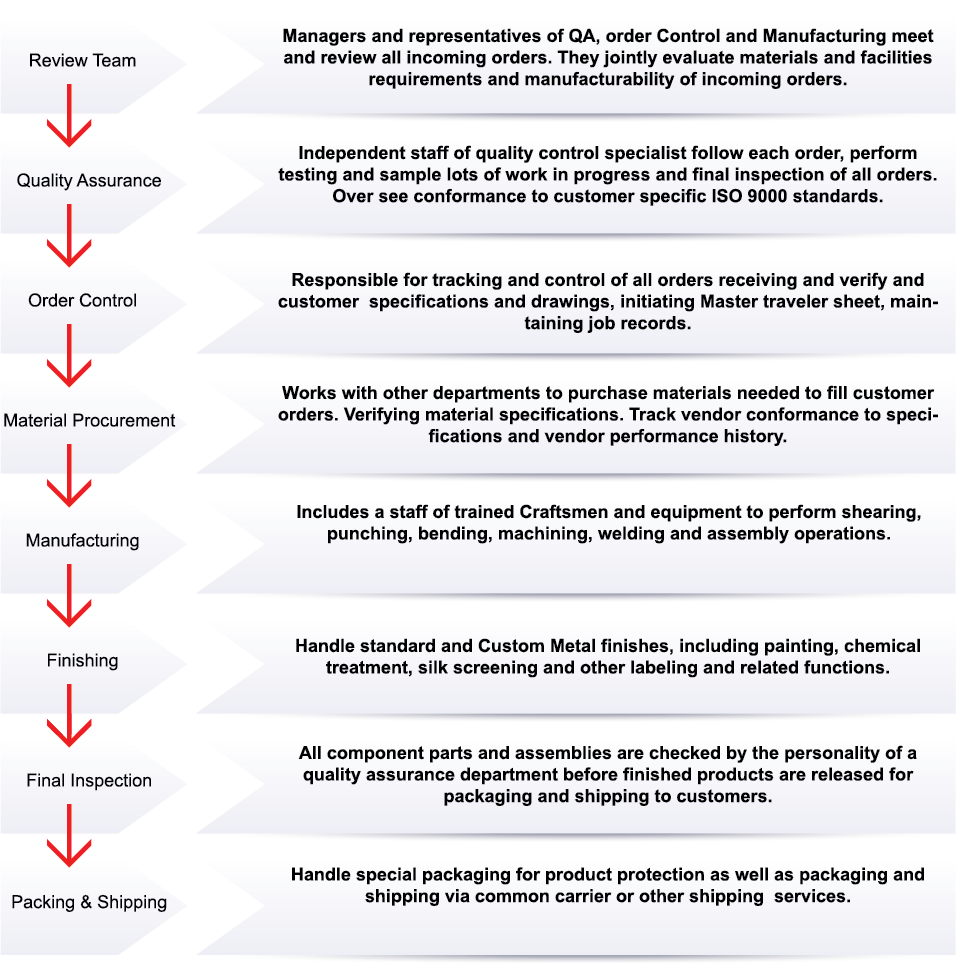

Since 1980, Behl Precision Fabricating has provided precision sheet metal products for the electronics and related industries. Conveniently located in Stafford, Texas, just outside of Houston, our primary focus is customer satisfaction. We deliver a quality product, in a timely manner, at a reasonable cost. Our "State of the Art" facility, with the very best equipment available, is certainly essential to achieving that goal. However, the total attention given to producing quality products by all of our employees is the key to our success.